Everything you need to know about OEKO-TEX® certification and why sustainable textile and leather products are more than just a trend in the field of occupational safety.

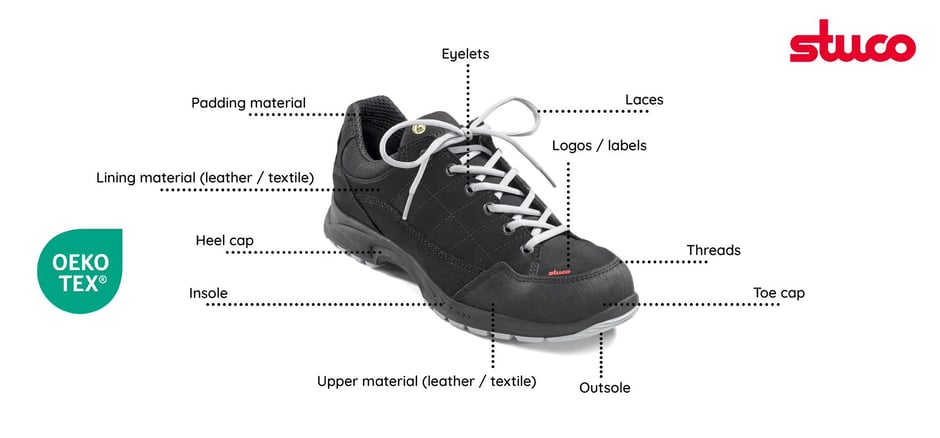

It takes over 250 work processes and more than 60 individual components to produce a comfortable, high-quality pair of safety shoes. Every single component, including the non-textile ones, from the leather to the rubber and the threads to the individual eyelets, is laboratory tested by OEKO-TEX® for harmful chemical residues. We have successfully certified four models with the OEKO-TEX® LEATHER STANDARD label and further models are in the process of being certified.Safety and work shoes screened for harmful substances in accordance with the OEKO-TEX® LEATHER STANDARD.

The manufacturing process for some materials, such as tanning leather or dyeing yarn, requires the use of certain chemicals. The OEKO-TEX® LEATHER STANDARD label shows customers that the product was made using materials that do not contain any chemicals known to be harmful to health.

An independent OEKO-TEX® partner institute checks the individual components of the product using a global, standardized OEKO-TEX® catalogue of criteria that contains several hundred regulated individual substances. The testing criteria and threshold values are often stricter than national and international regulations, and contain various parameters aimed at health care. OEKO-TEX® updates the testing criteria at least once a year, taking into account the latest scientific findings and changes to the relevant legislation.

The testing of the Black & Black Stuco shoes included every single component of the shoes. The picture shows the individual components of the shoes that were tested.

Our commitment

Our focus is always on the values of sustainability, quality and safety, from the design of the shoe all the way to the use of sustainable and environmentally friendly products at our own European production facilities. The environmental sustainability of our OEKO-TEX®-certified safety and work shoes can now also be put to the test by the wearers.

Our certified shoe models

Excellent quality, outstanding wear comfort and uncompromising safety have always been the hallmarks of Stuco safety and work shoes. The OEKO-TEX® label now assures the wearer that the materials used in the shoes are not only safe and comfortable, but also environmentally friendly and free of harmful chemical residues.

OEKO-TEX®-certified work shoes with toe protection

The popular "Black & Black" model is available as an ankle-high safety boot or safety shoe. Both models have ergonomic steel toe caps and anti-perforation insoles for the optimal protection of your feet.

The following work shoes are suitable for environmentally conscious wearers who need toe and/or puncture protection while carrying out their work.

Art. 34.360 Size 36 – 48 |

Art. 29.360 Size 36 – 48 |

|

|

Black & Black high ankle safety boots S3Sporty, light and modern. The ergonomically shaped steel toecap ensures that the toes are optimally protected.

Article number: 34.360 . |

Black & Black Safety Shoe S3Sporty, light and modern. The ergonomically shaped steel toecap ensures that the toes are optimally protected.

Article number: 29.360

|

OEKO-TEX®-certified work shoes without toe protection

The popular "Black & Black" model without toe protection with an anti-perforation insole is available as an ankle-high work boot or work shoe.

The following work shoes are suitable for environmentally conscious wearers who prefer a sporty, light shoe without toe protection, but with puncture protection while carrying out their work.

| Art. 30.023 Size 36 - 48 |

Art. 20.053 Size 36 - 48 |

|

|

|

Black & Black ankle work boots O3Sporty, light and modern.

Article number: 30.023 |

Black & Black work shoes O3Sporty, light and modern.

Article number: 20.053

|

You can find more work shoes with or without toe protection here

Frequently asked questions about OEKO-TEX®

The material testing according to OEKO-TEX criteria is performed out by an accredited and independent test laboratory. In our case, the OETI - Institute for Ecology, Technology and Innovation in Vienna. The type testing in accordance with EN ISO 20345 and 20347 for personal protective equipment was done by BIMEO in Budapest. BIMEO is also an accredited testing institute that specialises primarily on protective products.